Walkabout: The Devil’s Weed, Part 2

Read Part 1, Part 3, and Part 4 of this story. The cigar manufacturing industry was huge in the late 19th, early 20th century. Every major city had literally hundreds of cigar factories; smaller cities had dozens, and even small towns often boasted of one or two. These factories ranged in size from large, multi-storied…

Read Part 1, Part 3, and Part 4 of this story.

The cigar manufacturing industry was huge in the late 19th, early 20th century. Every major city had literally hundreds of cigar factories; smaller cities had dozens, and even small towns often boasted of one or two.

These factories ranged in size from large, multi-storied buildings where tobacco could be stored as well as processed and shipped, to storefront tobacco shops that rolled their own, to a tenement table top.

Real men in those days smoked cigars, and everyone, from a longshoreman on the docks to the robber barons of Wall Street, smoked a stogie. Some people chewed tobacco, which was pretty vile; cigarettes were not yet all that common at the time, so the cigar was the most popular tobacco vice of choice.

Of course the quality of those cigars varied greatly, but they all had one thing in common – a human hand had to pack and roll the tobacco to make that cigar.

Last time we looked at a brief history of cigars and their manufacture. New York was the second largest cigar manufacturing state in the country, beaten only by Pennsylvania, believe it or not. 41% of New York’s cigar manufacturing was done in Manhattan alone, which had 5,000 factories of all sizes and shapes.

Brooklyn had over 900. The larger factories were unionized by the 1880s, and many of the workers were Spanish-speaking, mostly from Cuba and Spain. The rest were generally Germans and Bohemians, from that part of Central Europe that today is the Czech Republic.

In a tradition that continues today, the Cubans are generally considered to be the masters of cigars, and many of the 19th century factories were staffed and/or owned by Cubans and Spaniards.

It’s generalizing a bit, but most of the higher end cigars were made by the Spanish and Cuban factories. The workers there were higher paid, even though their output was lower than those made by other factories.

They also used Cuban and Sumatran tobaccos, a much finer grade of tobacco than the home-grown American variety. A member of the Cigar maker’s Union had to have a three year apprenticeship before being eligible for journeyman status, and full membership in the union.

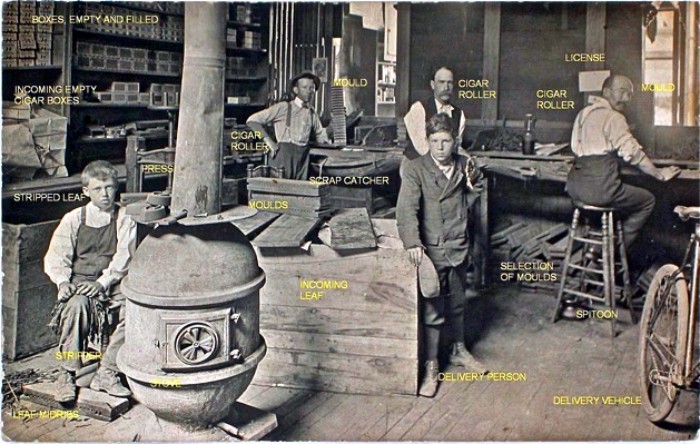

The very small cigar factories, the “Mom and Pops,” were disdainfully called “buckeyes” and “chinchallas” (cockroaches) by the larger factories. They employed less than ten cigar rollers, and many were family operations that had only two or three rollers.

These operations comprised 70% of the number of factories in the statistics. They were run in sheds, attics, storefronts, private homes and tenements. The goods were sold to wholesalers who distributed them under many brand names, and the quality of the product varied greatly.

Medium sized factories employed from 10 to 99 rollers. They were usually in larger towns and cities, and were housed in multi-storied buildings where the different operations were performed on different floors.

Tobacco storage, sweating and blending took place on the first floor; the cigars were manufactured on the second floor, and packed and shipped from the top floor. If the factory was in a good commercial area, the first floor would also be used as a retail shop.

Most of the product from these factories was wholesaled out. The railroad insured deliveries across the country and to more isolated areas. Many of the actual rollers in these factories were women.

The large factories had 100 or more rollers. They could make 25,000 cigars a day. In 1885, there were 24 huge factories in the US that had 500 or more rollers, three had 1,000. They could manufacture a quarter million cigars a day, or 50 million a year.

They made their own brands, or could private label to anyone who wanted their product, and sold to wholesalers, jobbers and retail stores. The demand for cigars was so great that all of these factories, large and small could make money.

All of this production needed a lot of workers, and although by this time only men smoked cigars, at least in public, women and children played important roles in their manufacture.

Cigar rolling took agile fingers. Ideally, a good cigar roller started as a child, with the nimblest fingers of all. Teenage girls were also desirable, as they made the best workers in the larger factories. But as production increased, quality decreased, so you basically had two completely different industries.

The famous Cuban cigar makers were men, and they trained since boyhood in their crafts. They made a higher grade product, all hand rolled with superior tobacco leaf, hand cut to use the best of the leaf in the center pack, as well as in the leaves that rolled around them.

They knew how to shape the cigars, with larger centers, tapering down to more slender ends, and did so with experience. They knew how much moisture was needed to make the tobacco adhere to itself. These were the highest paid craftsmen.

Below them were rollers of lessening ability, from different nationalities, and on the bottom were the factory workers who churned out thousands of cheap cigars made in molds. Instead of gently shaping the cigar with carefully cut leaves, these were made by packing tobacco into a mold and quickly wrapping it.

The factory owners did not want their rollers lingering over a perfect product, they wanted volume. This piecework could also be easily be taught to new workers who did not have any experience in rolling at all, and in short order, they could be producing product by the hundreds a day.

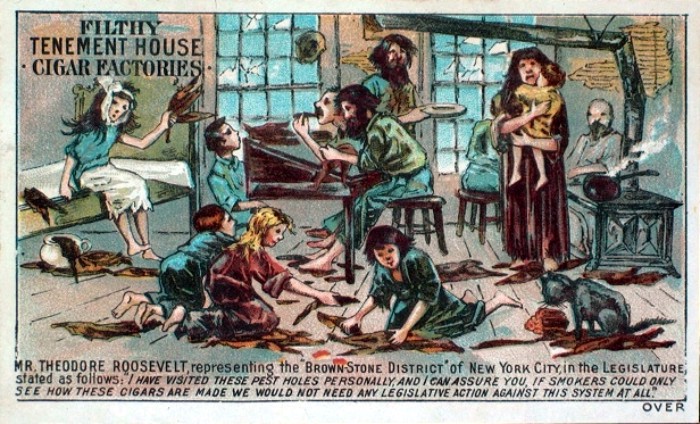

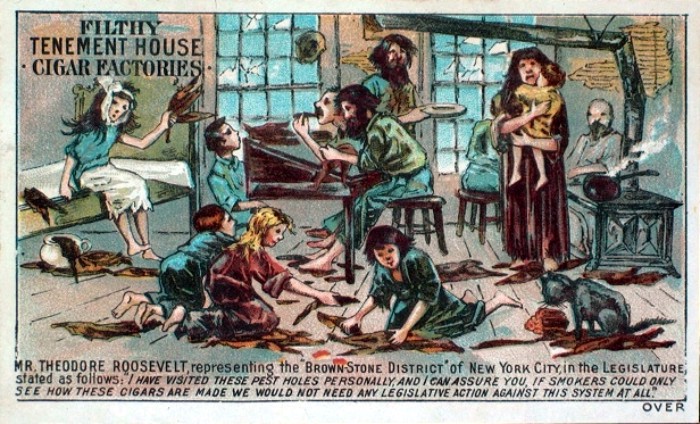

This mass production produced all kinds of cheap product, and it also gave way to the worst in industrial abuse of workers, especially women and children. This came in the form of the “cigar tenements.”

In New York City, Brooklyn, and other cities, the cigar tenements were an urban form of sharecropping. The factory owner owned the buildings, which were full of families who were slaves to the cigar industry.

These were mostly new immigrants to the United States; Poles and Bohemians, who had come here with nothing, and were uneducated and dirt poor peasants. Unscrupulous cigar manufacturers hired these families, put them up in their buildings, and had them making cigars at home.

The entire family worked to produce cigars in their small flats, competing with cockroaches, rats and mice for space in the rooms. The children remained unschooled, and no one learned English, or any other skills, helping to further guarantee that they remained in their state.

The workers worked day and night to meet the quotas, while continuing to live in the worst conditions imaginable. We’ve all read about and have seen photographs of the piecework garment workers of the Lower East Side, and as horrible as their conditions were, the cigar makers were worse.

Social reformers referred to these factories as “dens,” their conditions especially foul and dangerous for the thousands of children who worked in them. The children who worked alongside men and women were generally from 9 to 14 years old. Some were as young as 5.

There were some child labor laws in place in the 1880s, and they were supposed to insure that no children under 13 were to be employed in factories, but inspectors were not required to be in places with less than five employees, so there was no danger of being closed down by inspectors who may not have been able to find these places in the first place. Besides, these “factories” were actually home.

Most of these workplaces had little or no ventilation, so that tobacco dust was everywhere, on everyone and everything, and being breathed in regularly. Children were suffering from lung diseases like consumption right and left.

They were also barely eating, taking only the time to wolf down a “poor man’s sandwich” which was a bit of bread between two pieces of bread. Children and adults lived surrounded by tobacco scraps on the floor, which found their way under beds and tables, where they rotted, smelled, and drew vermin and insects.

Personal sanitation was lax, poverty and squalor pervasive, and all to produce enough cigars as to pay the rent, in order to stay in the tenement, which required you make cigars. It was a vicious circle.

On top of the horrible conditions for those producing the cigars, the product would have churned the stomach of those who smoked them, had anyone cared to find out. The tobacco was inferior anyway, but was stored and moistened for use in filthy conditions, made by people who were not themselves clean and not especially healthy either.

Consumptive people were coughing and expectorating all over the tobacco, while using leaves that were being chewed by rats, and harboring roaches. Sometimes saliva was used to moisten the leaves and finish off the cigar, and the same hands that changed diapers in a corner were then wrapping cigars moments later.

The cigar unions were furious at this activity. A moral sense of indignity that people were living that way was mixed more with financial outrage, because the tenement factories were producing an inferior product that was cutting into their bottom line.

Many of the tenement workers were also brought into the larger factories as scabs when the unions went on strike. Factory owners were also complaining that the tenement cigars were going out into the market as bootleg product, without taxation.

The government, both federal and local, was making a tidy penny in the taxation of cigars, but tenement cigars often were sold illegally.

The Cigar Maker’s Union was a powerful force in the legitimate industry. But although thousands of factory workers were women, the Union did not admit them, it was for men only. Female cigar workers made the same product as their male counterparts, but were, of course, paid much less.

Records show they made half of what the men made. The larger factories employed a lot of women, especially when the new cigar molds and cigar making machinery were introduced into the industry towards the end of the century.

The machines took quickness and dexterity, and the ideal woman operator was between 16 and 25 years of age. Some of the smaller factories did not hire women at all because they would have been forced by law to have a separate bathroom for them.

Being a woman or child in the cigar industry was tough. The entire industry, for so long fondly thought of as being a skilled craft for Spanish-speaking experts in fine cigar crafting, was really just another exploitive and dangerous factory job. So what happened to Brooklyn’s cigar makers? The conclusion of the Devil’s Weed on Thursday.

(Above – Political cartoon, late 19th century. Cigarhistory.info)

What's Your Take? Leave a Comment