Walkabout: The Ward Bakery Company, the Snow-White Temple of Cleanliness, Part 1

Read Part 2 and Part 3 of this story. Many fortunes have been made by providing the public with the basic products of life. One doesn’t always need to reinvent the wheel. Take bread, for instance. For centuries, people have made their own bread. But for almost as long, there have been bakers who would…

Read Part 2 and Part 3 of this story.

Many fortunes have been made by providing the public with the basic products of life. One doesn’t always need to reinvent the wheel. Take bread, for instance. For centuries, people have made their own bread. But for almost as long, there have been bakers who would do it for them. No one ever turned away a good baker.

For the busy urban household, bread making was time consuming, even for servants. If you’ve ever made bread, you know you have to set the yeast, mix the ingredients, let the bread rise several times, beat it and knead it to create gluten, and then let it rise again before actually baking. Or you could go to the baker and buy it.

The baker would also be able to make different kinds of bread, perhaps rolls, too, and even pastries. A baker and his bakery was an important part of the community. Interestingly, for centuries in Europe and America, the baker has generally been a man.

In 1849, a baker named James Ward and his son Hugh opened a one-oven bakery on Broome Street in Manhattan. A few years later, in 1852, Hugh and his wife Eliza welcomed young Robert into the world.

Robert was born to a world of flour, baking and hard work. When he was only eight, the Civil War began. Because of the lack of help available because of the war, young Robert had to step in to help with deliveries, running all over New York with his baskets of bread.

A few years after that, Hugh Ward moved to Pittsburgh and opened a bakery there. Robert stayed in New York, attending school, and then business college. In 1884, Robert moved to Pittsburgh, and he and his father and younger brother George opened another bakery together, under the name R. B. Ward Company.

That same year, Robert and his wife Mary Catherine had a son, William B. Ward. The Ward bakery business continued to grow; the R. B. Ward Company merged with another bakery, and became the Ward Mackey Company of Pittsburgh.

That led to the creation of yet another company, this one called the Ward Corby Company. They operated bakeries in Cambridge, Providence and Chicago. That, in turn led to their acquisition of yet another company, the Ohio Baking Company, in Cleveland.

Robert and his family now had quite a conglomeration of large bakeries from the Midwest across to the Atlantic States. They decided to combine them all into the Ward Baking Company, and enlarge their operations by opening baking facilities in New York, Brooklyn and Newark. The year was 1900.

The Ward Baking Company’s New York operations were designed to manufacture bread for the New York area market only. To do so at the volume needed in a city of millions, they needed to build several new factories.

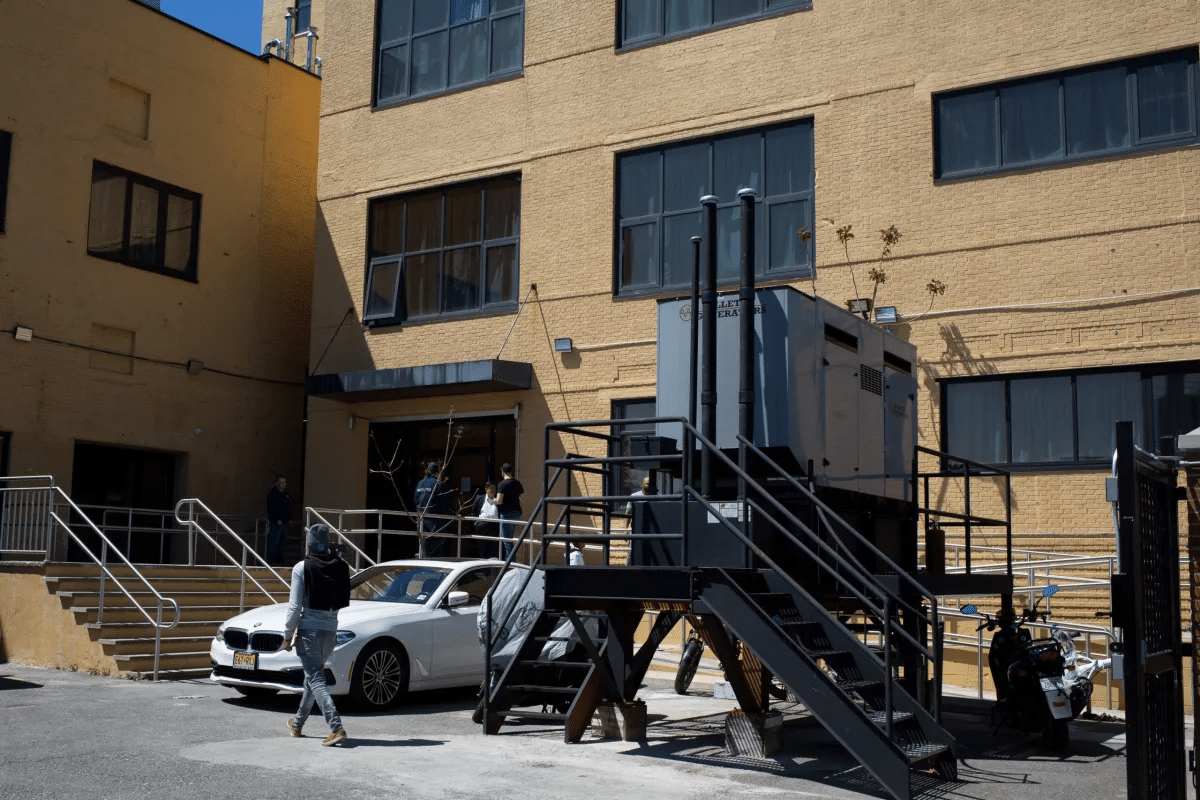

Land was secured in Newark, the Bronx, and on Pacific Street and Vanderbilt Avenue, near the Atlantic Yards of the Long Island Railroad, in Brooklyn. The Brooklyn Eagle records in 1910 that 23 lots on Pacific and Dean Streets were purchased for the new facility.

The land cost Ward around $75,000. It was purchased from the Moran estate, and was chosen in part because of the proximity of the railroad yards, which could facilitate the delivery of materials through its freight yards.

In 1903, the Ward Bakery Company was the first company to erect and operate a modern, sanitary bakery in Pittsburgh. They wanted to bring that high level of modern operation to all of their facilities, and wanted their new New York and Newark bakeries to be the poster children for 20th century industrial baking. The design and operation of these bread factories would be state- of-the-art.

Back in Pittsburgh, in 1909, Ward had established a Baking Research Fellowship at Mellon Institute, under the direction of Dr. Robert Kennedy Duncan. Fellowships were offered to chemists specifically to improve the chemical properties of flour and yeast. Under this program, Dr. Duncan and his team developed a new kind of yeast food that produced a superior loaf of bread.

Although Dr. Duncan died before the process was completed, the Ward brothers wanted to honor his achievement. They named the new yeast Arkady, after Duncan’s initials. The formula for Arkady yeast was purchased by Fleischmann’s Yeast in 1924.

In 1910, with his land secured, Ward made an unusual and rather brilliant business decision. He took the architectural firm of C. B. Comstock, his planners and financial team and they all went on a cruise to Europe. While there, they toured famous buildings and looked at European manufacturing, and then took the ship back to New York.

By the time they arrived home, they had planned the factories down to the last nail. Ward told a reporter, “We were gone some thirty days and when we returned the plans were completed. They were made literally in mid-Atlantic. I took this novel course so as to be entirely free from the usual interruptions of business in an office.”

Between the Bronx and Brooklyn plants, which were very similar in design and shape, Ward spent over two million dollars. The plants were designed in a very classical style, inspired by Greek architecture. The Brooklyn plant was five stories tall, while the Bronx building was six.

Ward considered the Bronx facility his headquarters, which made sense, as he lived in New Rochelle. Both buildings were clad entirely in white glazed terra cotta tile, giving them a gleaming presence in the communities. This was the outward manifestation of the sanitary operations going on inside.

Ward Bakeries boasted its “Tip Top” bread, and all of its bread products were made without the hand of man ever touching them. His advertising called the factories the “snow-white temples of cleanliness.”

The bread making process was pretty impressive, especially for its day. In 1915, the Brooklyn plant used a thousand pounds of yeast a day. They used 25 barrels a week of condensed milk, each barrel weighing 625 pounds each. They used a ton of vegetable oil to grease the bread pans, and sugar was purchased, “by the car load.” A loaf of bread was made thusly:

The flour is unloaded from the freight can it came in at a special siding in the sub-basement. The flour is stored in two-bushel sacks in a warehouse space that could hold thousands of tons of flour. The sacks of flour are hoisted up from storage and run through a giant sifter that separated the flour from dust, lint and other particles.

The pure flour flows though pipes in the floor, and then up to the top floor of the building, into huge tanks, where machinery measures it, and cuts off the flow when the correct amount is in the tank. Distilled water, yeast and sugar are added, and the dough then flows out into huge troughs, and allowed to stand.

After the dough has ripened, it is forced down openings into mixers below. Machines that look very similar to cement mixers spin the dough around, stretching it and activating the gluten. After the allotted time, the dough is dumped into a huge trough like a giant bread pan, and a single loaf, weighing almost a ton, is allowed to rise.

The trough is on overhead rollers, and when the dough has risen sufficiently, it is rolled by a track suspended on the ceiling until it is over another an opening in the floor. The bottom drops out of the pan and the dough is guided down to the floor below, where it enters the top of another giant machine.

This machine grabs the enormous mass of dough and slices it to pieces, each piece the correct size for a loaf of bread. The pieces pass down a conveyer belt where they are molded into the correct shape and covered with flour. The pieces continue down to another platform where another conveyor belt holds the empty oiled bread pans.

Each lump falls precisely into the pan, and this conveyor belt leads right into the mouth of the oven. Another machine with claws like a gigantic insect grabs sixteen of the loaves and places them on a moving platform. That platform moves through the oven, overseen by human workers to make sure the bread is baking uniformly and correctly.

When the bread comes out of the oven, the loaves are shaken loose from their pans onto another conveyor belt. That belt takes the bread down to the next floor below where another ingenious machine grabs a loaf and wraps it in waxed paper, and seals it with a seal and stamp. The bread is never touched by a human hand. Bread was not factory sliced back then.

The bread is then gathered into large bins that continue down the conveyor belts, where they are loaded onto the trucks and are off to be delivered. It was a long way from Grandpa Ward kneading his bread by hand on Broome Street.

Next Chapter: Robert Ward had only one hobby – he loved baseball. He put his considerable money where his passion was and funded a team that helped shape Brooklyn baseball history. More on the Ward Bakery and the Ward family story, next time.

Pechter’s

Yes, the tragedy is the beautiful white terracotta building was still standing until Bruce Ratner and his Atlantic Yards project tore it down. There was quite a large amount of outcry to save it.

The greatest invention until sliced bread!